Chemical Spill Management: A Comprehensive Guide

Spilt chemicals pose serious hazards. Workers can suffer anything from slip-and-fall injuries to chemical burns or toxic exposure if a spill is not controlled promptly. Regulations in the UK’s health and safety laws explicitly require businesses to have measures in place for chemical spills and to train staff in emergency spill response.

In this comprehensive guide, we will outline how to prepare your workplace with risk assessments, spill kits, training and the step-by-step chemical spill response procedure, as well as special considerations for different types of spills.

Why Chemical Spills Are a Hazard in the Workplace

Chemical spills in the workplace present multiple risks that employers must address. Hazardous liquids can cause immediate injuries, such as skin burns, poisoning, or respiratory harm, as well as creating indirect dangers like slippery floors or fire hazards. A significant spill can not only injure personnel but also damage property and contaminate the environment.

This is why performing thorough risk assessments is crucial. To find out how to carry out a successful risk assessment, read our guide on the topic.

The Benefits of Chemical Spill Kits

When chemical spills are likely, it’s important to have all the equipment you need easy to reach for in one place.

At SpillShop, our chemical spill kits provide all the essential supplies needed to tackle a hazardous liquid spill conclusively and efficiently by having everything you need in one convenient package. These kits, available in various packaging from shoulder bags to wheeled bins, allow for a swifter, less hazardous clean-up process, reducing the potential for accidents. Chemical spill kits prove to be a cost-effective option, giving workplaces the ability to tailor the quantity and size of equipment and consumables needed to the size of their business. Plus, when all disposable resources are spent, we offer affordable refills to ensure your kit is always ready for the next spill incident.

Our chemical spill kits are available in three size categories: small (15L to 60L), medium (65L to 240L) and large (250L and 1100L).

What Should Be in a Chemical Spill Kit?

The exact contents of a chemical spill kit can vary by kit size or type, but all these kits share the same core components designed for both containment and clean-up. This includes:

- Absorbent pads and mats: These are flat absorbent sheets used to soak up spilt liquids. They are usually chemical-resistant and can absorb acids, caustics or solvents depending on the kit type.

- Absorbent socks or booms: These flexible tubes are placed around the edges of a spill to stop it from spreading.

- Absorbent cushions or rolls: For higher-volume spills, cushions can be placed into puddles of liquid to absorb a lot at once, while rolls of absorbent material can be torn off to cover large surface areas.

- Disposal bags and ties: Strong plastic bags are provided for safe collection and disposal of used absorbents and contaminated debris.

- Instruction sheet and contents list: To ensure users respond to spills in the correct order and keep track of the kit’s proper inventory.

These core items ensure you can contain and absorb most chemical spills effectively. In addition, many chemical spill kits come with special tools for specific scenarios:

- Drain covers/plugs: To quickly cover floor drains and prevent spilt chemicals from entering the drainage system.

- Barrier tape: To cordon off the affected area.

How to Clean Up Chemical Spills

If you spill a chemical, what should you do? The following is a step-by-step chemical spill response procedure that can serve as a general guideline for most workplaces. For acceptable preparation, employees must be trained on how to use spill kits for an effective response. Learn more about spill kit training here.

What to Do Before Starting Chemical Spill Clean-Up

Never attempt to clean up a chemical spill without wearing suitable personal protective equipment (PPE). At minimum, this usually means chemical-resistant gloves, safety goggles or a face shield, and a lab coat or coveralls. For larger spills or highly dangerous substances, additional PPE such as respirators or chemical suits may be necessary. Ensure that all PPE is in good condition, without any tears or leaks.

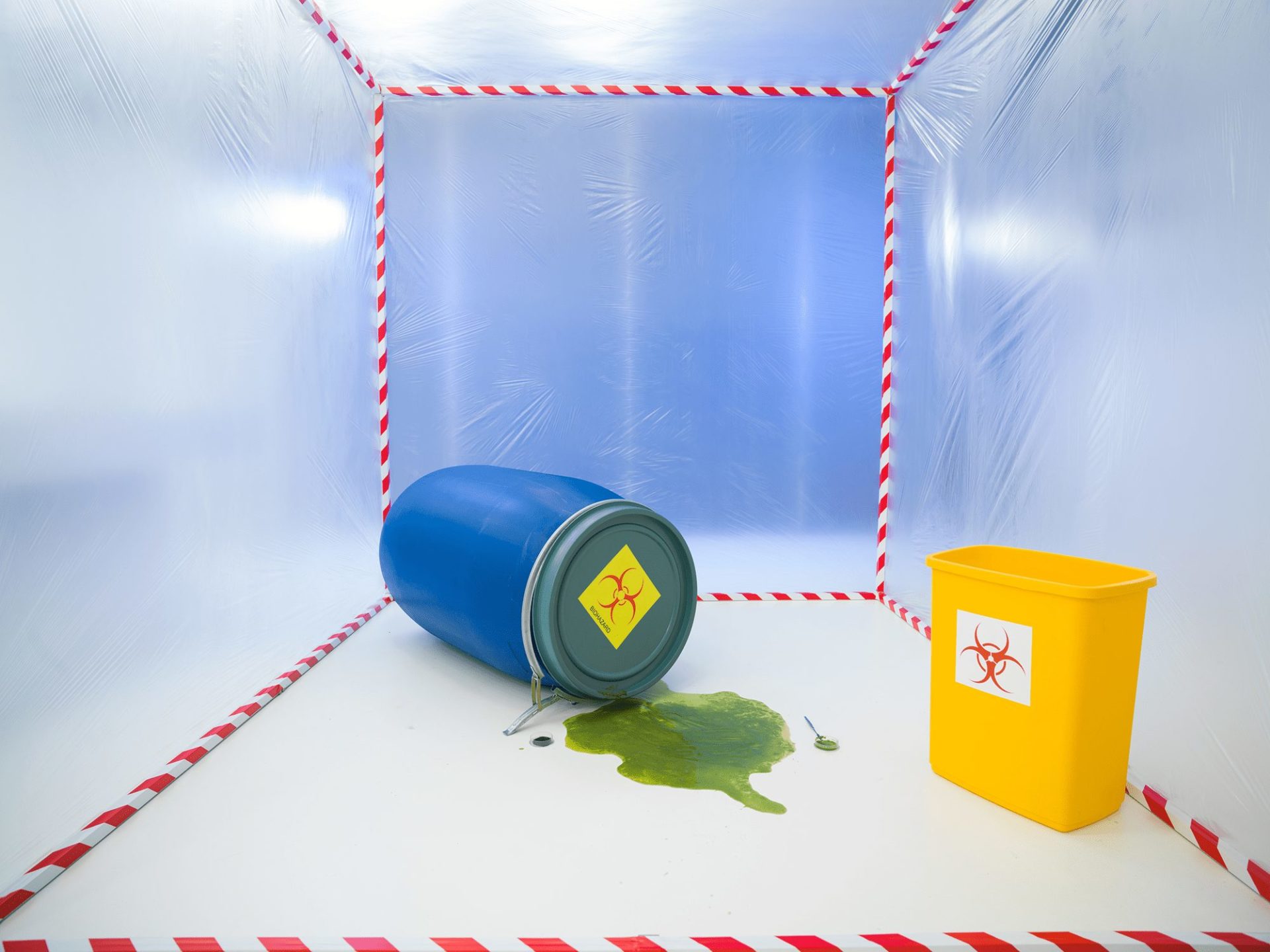

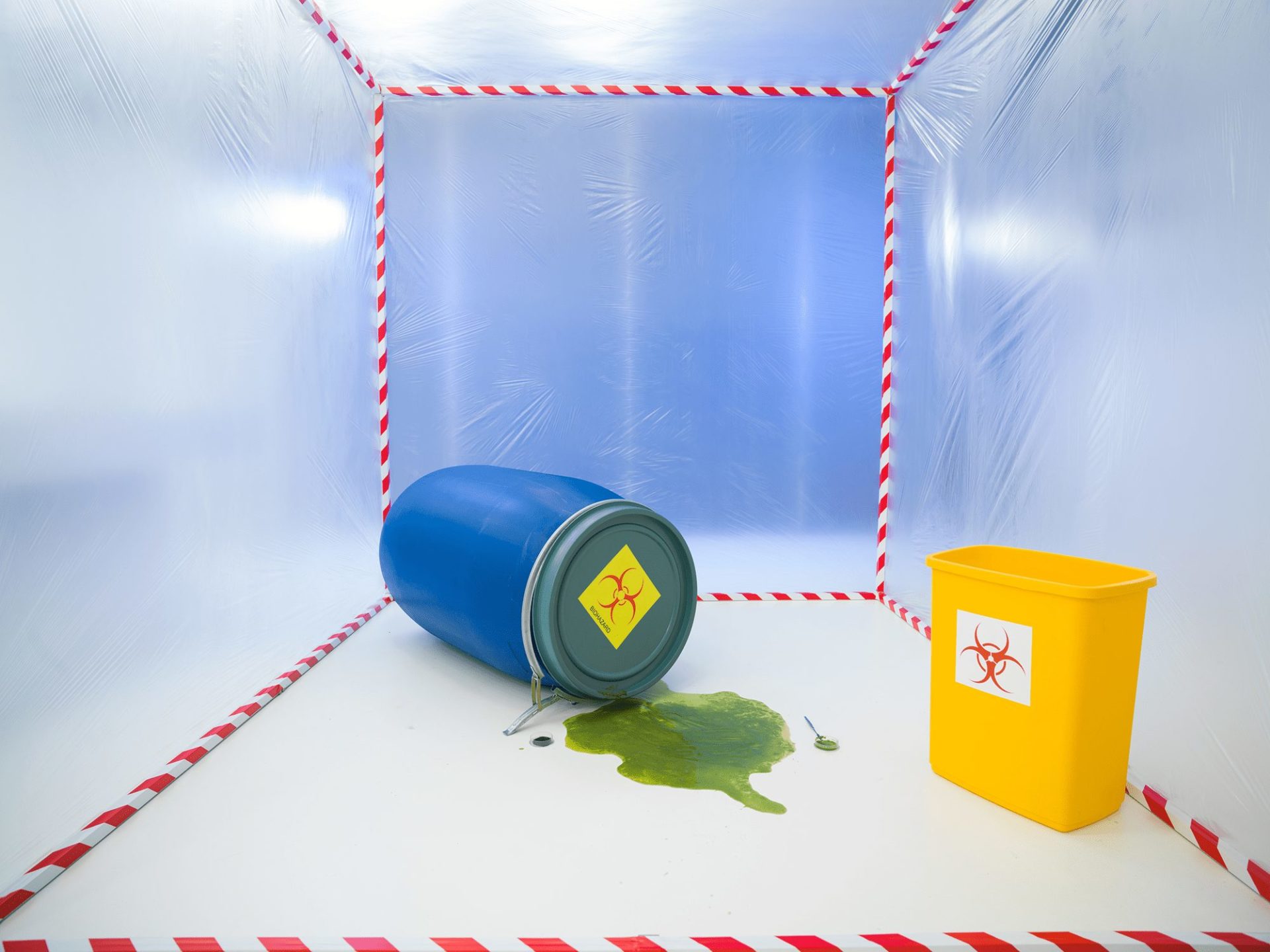

Stopping the Spill from Spreading

Before focusing on clean-up, halt the ongoing release of the chemical, whether that means upturning a tipped-over container, closing a leaking valve or using a drain plug to temporarily seal a leak. Then, use the absorbent socks or booms from your spill kit to encircle the spill and create a barrier. This will block the flow of the chemical.

Absorbing and Cleaning Chemicals

After containing the spill, absorb the liquid using your spill kit’s pads, pillows or absorbent powder. Work from the edges of the spill toward the centre so that you gradually make the spill area smaller and avoid pushing the chemical outward. Gather up all used absorbent materials using a broom or shovel (not your hands) and place them into the disposable bags contained in the spill kit.

Disposing of Equipment After Use

Seal the waste bags or containers and clearly label them with contents. Depending on your site procedures, you may need to contact your Environmental Health & Safety office or a licensed hazardous waste disposal contractor to pick up and properly dispose of the material. Once the used materials have been promptly disposed of, clean the spill area to eliminate residues.

Case-Specific Considerations During the Clean-Up Process

Many chemicals may inhabit your workplace, and some require extra precautions during clean-up due to their unique qualities. It’s important to adjust your response depending on the chemical’s properties.

Flammable liquids, by their name, can ignite easily, so it is vital to eliminate all ignition sources immediately in the area of the spill. This includes extinguishing open flames and turning off spark-producing equipment. Once the area is cleaned, use controlled ventilation to disperse the vapours of the substance, as these too are liable to combust near an ignition source. All absorbent materials used should be placed in fire-resistant, heavy-duty bags or containers, sealed and labelled for hazardous waste disposal. Finally, do not resume normal work in the area until you are sure all flammable vapours have fully vented out.

If the chemical spill is corrosive, use the correct neutralising agent available to you by sprinkling it carefully onto the spill once the spreading has been halted. Add neutraliser slowly and stand back to avoid any splashes.

Spills of highly toxic chemicals or solvents, such as mercury or pesticides, demand careful handling to avoid inhalation or absorption risks. As with flammable liquids, increase the ventilation to help disperse dangerous vapours. It may be necessary to wear a respirator if the chemical is extremely hazardous in the air. Use absorbents that minimise dust, such as spill cushions or absorbent pads, as they do not create the dust clouds that loose powder absorbents might.

Always err on the side of extreme caution with toxic spills. If at any point the situation seems beyond your capacity (for instance, the fumes are overwhelming or the quantity spilt is very large), evacuate and seek emergency HAZMAT support.

Choose SpillShop for Quality Spill Control

SpillShop is dedicated to helping businesses achieve excellence in spill preparedness. We offer not only a wide range of compliant, high-quality spill kits for every type of hazard, but also expert guidance on spill response training and best practices. Whether you need advice on selecting the right spill kit for your facility, our specialists are here to support you. Contact us today to learn more about our products and how we can help you prepare your workplace for any emergency.